Dave Schmeider

Originally when he left school, Dave Schmeider wanted just to work with wood, and

when he was offered a coopering apprenticeship at the Bundaberg Distillery he had

to ask around to find out what coopering was. But once he started, he fell in love

with a trade which he found was hard work, but very satisfying. He recalls that

it was still, in 1970, pretty much a traditional craft, mostly using hand tools.

‘We had a machine planer and an electric bow saw, but otherwise it was hand planes

and things like that’, he recalls. ‘We were mostly maintaining barrels then, not

manufacturing, but that was good, because manufacture was becoming merchandised even

then, and we still worked by hand’.

The manager at that time, Bill Eastwood, had a firm policy – rum stayed in wood until

it went into glass, and so every drop went out the door in barrels until the mid-seventies,

when a bottling plant was built in Bundy.

For Dave Schmeider, the irony of his career choice was that changes in technology

meant that demand for the coopers skills began to decline almost as soon as he learned

them. His response was to start, his own business, Schmeider’s Cooperage, in 1982.

He’s proud of the fact that he’s trained five apprentices over the years, and that

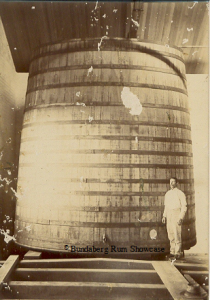

the business is still running successfully. And he’s still working at Bundaberg

Rum – he maintains their timber vats, and can tell them at any time the condition

of each individual vat. As well, Dave’s just started a huge task – rebuilding and

expanding big vats which need to be moved from a shed on Millaquin Sugar Mill land.

Dave sees a future for his craft – ‘People want hand made products like barrels,

even if it’s just for nostalgic reasons. And as long as it remains law that rum

must remain in wood for at least two years, there’ll always be a demand for the cooper’.

Peter Dixon

Peter Dixon presently drives a cane train for Millaquin Sugar Mill, but if he got

a chance to return to coopering he’d do it tomorrow. But it wasn’t like that when

he began at Bundaberg Rum as an apprentice cooper in 1964 – all he knew was that

at 15 years of age he didn’t want to stay at school. When he saw an ad for an apprentice

cooper at the distillery he had to ask his father to find out that the job had something

to do with making barrels.

It took only days to get the job, and Peter started in the hot, dusty coopers shop

under master cooper Alan Maxwell. At that time all rum which left the distillery

went out in wooden casks by train or semi-trailer. Casks were reused as many times

as possible, and inevitably they would begin to leak.

Peter’s first task was to use a hammer and driver to tighten the metal hoops that

held the casks together, but eventually he was entrusted with the higher skilled

task of shaping the wooden staves which make up the casks. All shaping was done

by hand with a jack plane. ‘One of my more unusual tasks was to take a sugar bag

and cane knife and ride my bike down to the swamp that then existed near the sugar

mill. My job was to harvest the bulrushes that grew there and to bring them back

and dry them’, he recalls. Later, the dried bulrush leaves were split and used to

caulk the gaps between the staves to make the casks completely watertight.

Peter still makes the occasional small barrel for people’s home bar, and remembers

his time at the distillery with great affection.

<<<PREVIOUS NEXT>>>